In the area of watch prevision CNC machining, ZESAD tool experts have developed numerous machining solutions in recent years. The focus has been on tools adapted to the related customer requirements. Along with these individual tool solutions, however, the usage of high-performance standard tools plays a major role in many applications. Therefore a comprehensive standard programme has evolved from these custom tools.

FOR ALL APPLICATIONS

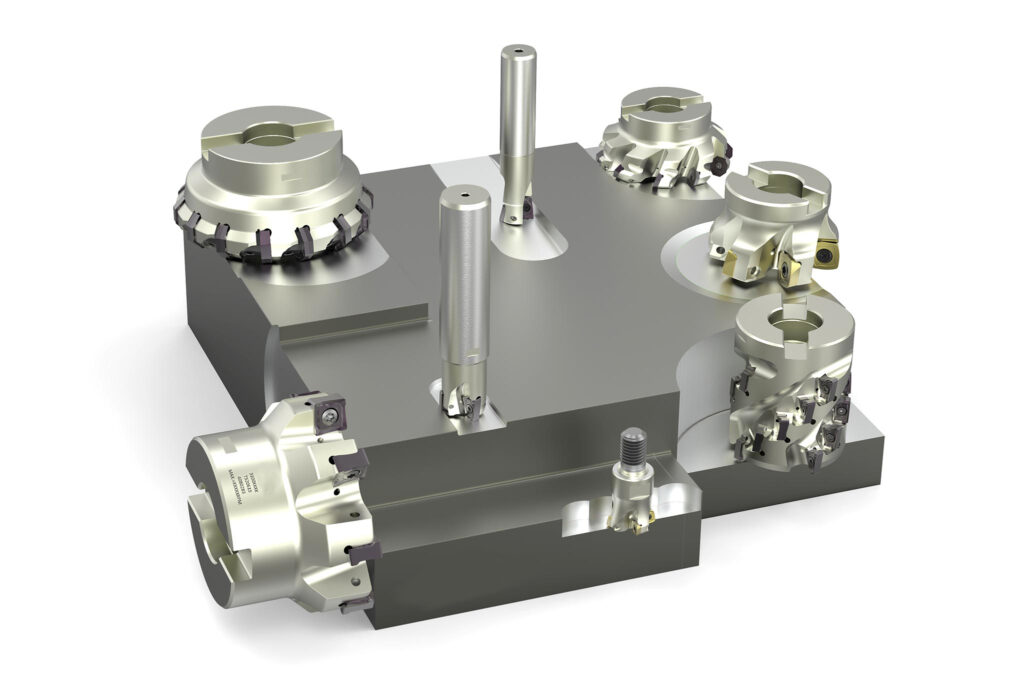

ZESAD offers a suitable tool for every milling task:

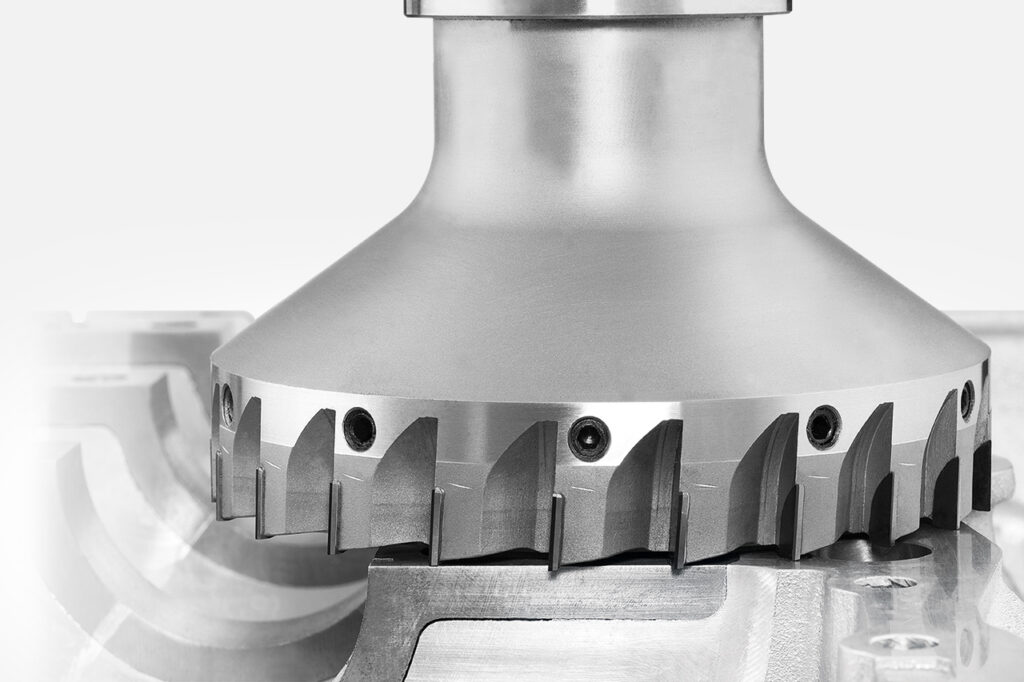

On the one hand end milling cutters with fixed cutting edges, on the other hand milling cutters with replaceable inserts.

All types of machining are covered with innovative tool solutions:

Whether general machining operation such as groove milling, face milling, shoulder milling, for roughing and finishing, or special machining operations such as trochoidal or helix milling –