Description

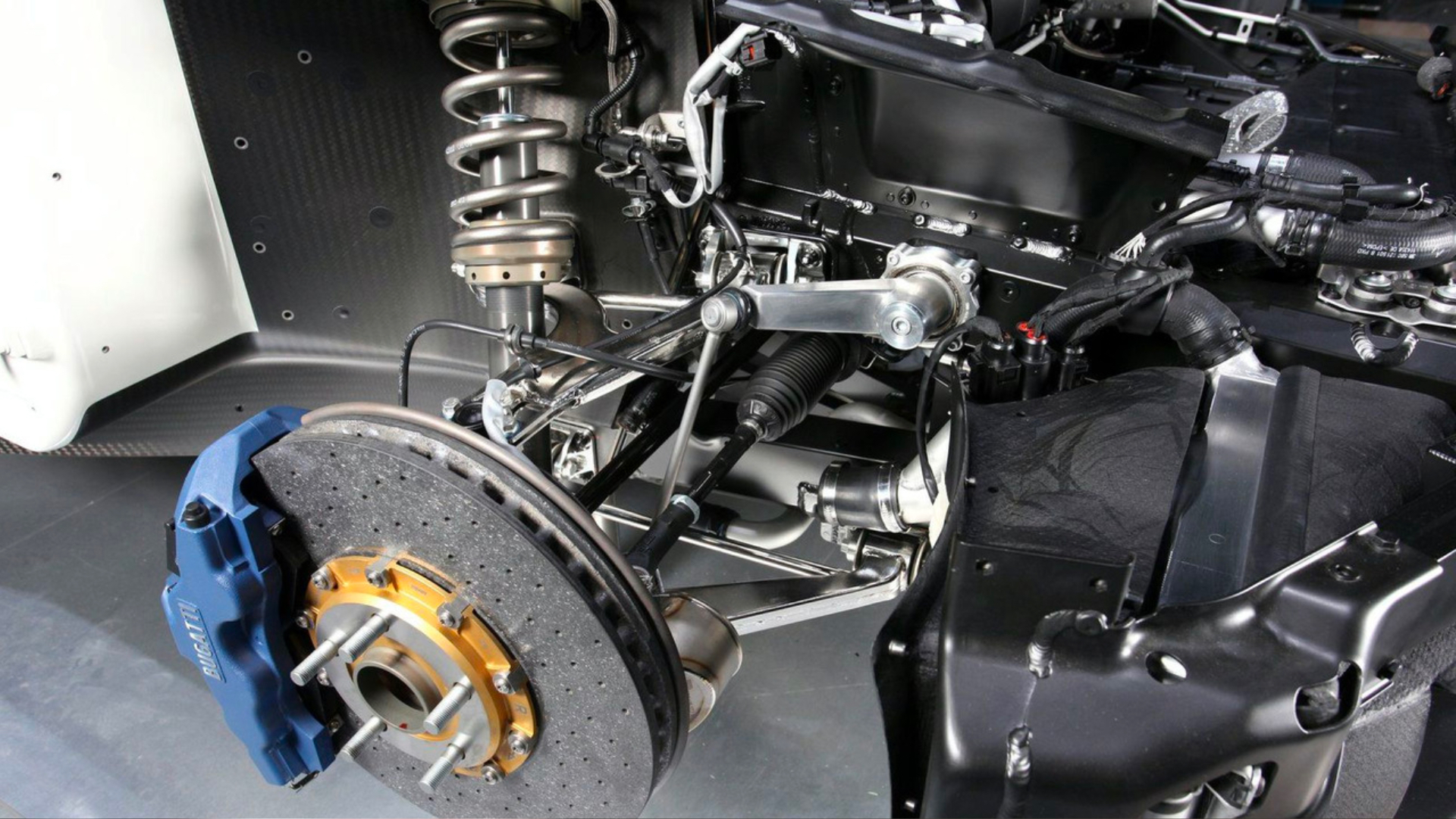

We design and manufacture an aftermarket lift-sytem for the Bugatti Bolide, according to your requirements. This is not just for looks, all design aspects of this product are calculated for optimal performance.

- 3D Scan of your existing car and related parts

- Surface Reconstruction of the Scan STL File to IGS/IGES/STP/STEP

- 3D Design for your custom requirements

- CNC Machined Spacers, milled from 6061 / 5083 aluminium

- Anodizing in a color finish of your choice

- Assembly with other parts if needed

- Designed to suit Bugatti Bolide

- To Suit Factory OEM Connection

- Designed for both track and personal-use application

The lift system for the Bugatti Bolide, made from Forged Aluminum. ZESAD products are certified by TUV, a German government approved authority for car safety standards.

The Bugatti Bolide has a superb performance , however with it lacking a lift system from factory, it can be a little difficult to use in non-track environments. We can assist you to design and manufacture better parts. The ZESAD Lift System really is the finisher to any Bugatti. The Bolide from factory has quite a low-sitting spec, despite its stark performance, that really prevents it from being used in non-track places. The ZESAD creation fits into the factory design, and a more aggressive but usable spec. It is absolutely integrated with the OEM specs, not looking aftermarket at all.

The Lift System is made up from lightweight and strong Forged Aluminum Spacers, produced via Precision Machining, giving both great strength and superior finish. Once the part has been CNC milled and pulled from the drilling room, it is checked and tested thoroughly before heading to anodizing. Each part is inspected further and checked for tolerances before being hand and machine polished, followed by being waxed and sealed if necessary, with high content Carnauba products.

Assembly with other milled parts, or accessories (O-Rings / Gaskets) will be the last step in the product manufacturing cycle.

Install:

This is a replacment part, the OEM system needs to be removed for installation. Although fitting is quite straight forward we do always recommend using a trained professional to undertake the install. We estimate around 1-2 weeks to fit.

Additional Details:

Vehicle heightening kit for more ground clearance. A ZESAD-heightening set consists of two spacers. One for the left and one for the right wheel of each axle. The patented spacer can be stacked on top of each other and thus allow a step-by-step raising of 12mm (1 set = 2 spacers) / 24mm (2 set = 4 spacers / 36mm (3 set = 6 spacers) / 48mm (4 set = 8 spacers). The spacers are black anodized and thus blend in visually discreetly with the strut/spring. Quality Made in Germany. Since each spacers are individually adapted to the respective shock absorber/suspension of your vehicle, we need the chassis number (VIN) of your vehicle after ordering. Through a modern 3D production process, you will always receive 100% precisely fitting goods. The delivery always includes all small parts and accessories as well as TÜV test certificates. The detailed assembly instructions with illustrations guarantee a simple and fast assembly. Since spacers are not a closed ring, they can be pushed directly into the shock absorber without removing the spring.

Fits: Bugatti Bolide only

Reviews

There are no reviews yet.